product ideas

Create new solutions

Technical Textiles are (customized) fibre layers where simple

solutions do not work - as there are automotive, spacecraft or

other branches of transportation in the need of outmost

flexibility and functionality.

Until now, this is quite expensive. V-Loom can shorten the

processes by including elements instead of attaching in the

aftermath.

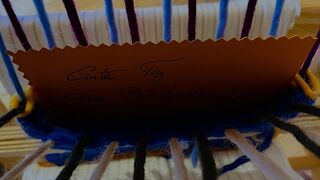

Steel wool and wire. Because of the V-Shed one can produce tech textiles with material unthought of before.

Used be also other fluffy material in combination with other extraordinary warp and weft.

double weave filled from above -

mats with brittle or sticky fiber,

cured or hardened while weaving,

as for cushions, protection, seed containers,

landscape protection, flexible structures

spacer fabric with closed sides -

filled with liquids, foam, particles,

homogen or with layers of additives,

as for more stiff structures, containing

pipes, sensor systems, electric parts

double weave with closed sides -

fabric containing elements as wide as

the loom is, and as long as the distance

between fell and cloth beam, as for

cabins, boxes, emergency services

Use fibres in a new way

Until today, every yarn or filament to weave with, is designed

to fit in a narrow tube, called shed, brought in at high speed,

being blown or shot.

The V-Loom technology provides an open shed, like a pocket,

into which you can fill, drop, pour, set everything what comes

to your mind.